Save Money with Commercial HVAC Maintenance

Evolution Maintenance

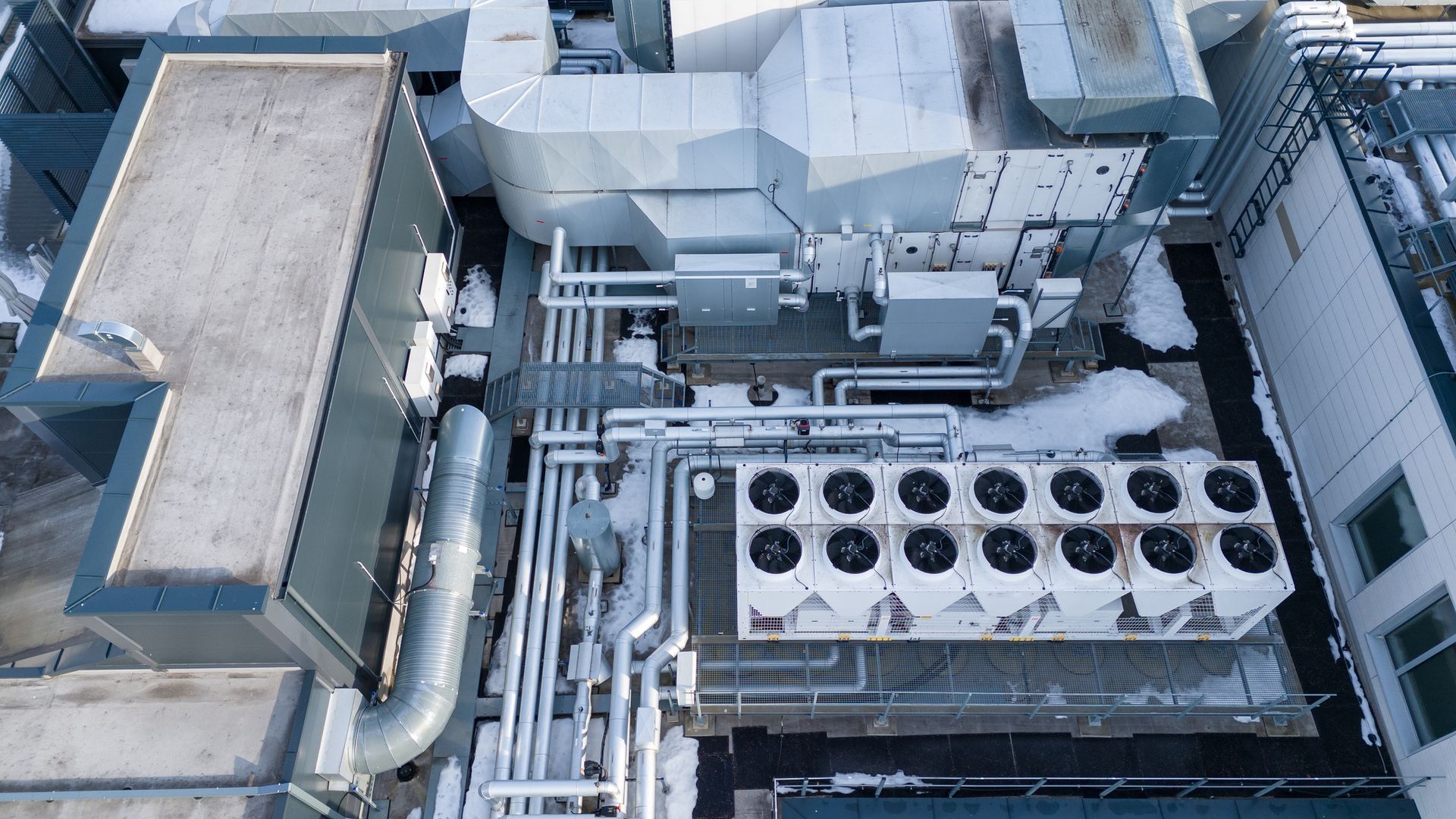

HVAC PREVENTATIVE MAINTENANCE IS A SMART INVESTMENT

The results are in: studies show that preventative maintenance on your commercial HVAC system is worth the investment. According to the Building Efficiency Initiative, less than 50% of companies surveyed perform preventative or predictive maintenance on their critical HVAC systems. Think of your heating, cooling, and ventilation systems as the circulatory system — the heart, blood, veins, and lungs — of your commercial enterprise. Poor circulation can cost your business money and your employees their health and well-being. You owe it to your business and your employees to treat your system to regular check-ups.

Industry resource, Buildings

magazine, notes that HVAC system maintenance is nothing compared to what you’ll spend in the event of a catastrophic system failure and that by tracking system indicators (as you would if you have established a comprehensive HVAC maintenance plan), you can identify potential emerging problems before they reach a crisis point. “Some aspects of a maintenance plan are simple – change the oil, change the belts, change the filters. But, to keep a system operating at maximum efficiency, you’ll need to expend more elbow grease beyond the basics from time to time. Air-handler coils need to be cleaned periodically to keep heat transfer at maximum amounts. Boilers need to be cleaned annually; even 1/16-inch of soot and ash on heat-exchange surfaces in an oil-firing boiler can reduce efficiency by 10 percent.”

Whole Building Design Guide

reports that “Heating, ventilating, and air-conditioning (HVAC systems) account for 39% of the energy used in commercial buildings in the United States. Consequently, almost any business or government agency has the potential to realize significant savings by improving its control of HVAC operations and improving the efficiency of the system it uses. The use of high-performance HVAC equipment can result in considerable energy, emissions, and cost savings (10%–40%).”

COMMERCIAL HVAC SUSTAINABILITY TIPS THAT SAVE YOUR BUSINESS MONEY

The US Department of Energy

states that the average commercial building wastes a whopping 30% of the energy that it consumes. That’s a lot of money floating in the wind. Keep those dollars in your budget with proper HVAC maintenance.

CHANGE AIR FILTERS REGULARLY

Plan on changing air filters on a quarterly basis. Ideally, filters will be changed monthly during peak heating and cooling seasons. Dirty filters cause commercial HVAC systems to work harder by restricting airflow and may result in a 5-10% energy loss. Dirty air filters also lead to poor air quality and may reduce the productivity of your employees.

INSTALL PROGRAMMABLE THERMOSTATS OR A ZONED HEATING SYSTEM

Programmable thermostats and zone heating systems can save your business hundreds of dollars each year while simultaneously saving the environment.

KEEP YOUR CENTRIFUGAL CHILLERS IN GOOD SHAPE

Enjoy up big savings by removing microbes, ensuring an adequate air flow rate, and achieving optimal refrigerant levels (Building Efficiency Initiative).

PROPERLY SEAL HEATING AND COOLING DUCT

Professional HVAC technicians can reduce energy waste by using foil tape or blown-in sealant to seal your ducts and by wrapping ductwork in insulation.

INVEST IN ROUTINE MAINTENANCE

Qualified technicians will develop a maintenance plan that could include regular filter maintenance, duct cleaning, moving part lubrication, sensor testing, and thermostat installation, calibration, and maintenance.

Think of preventative HVAC maintenance as you would a routine oil change in your car. Just as you wouldn’t risk your engine’s integrity by running on old, dirty oil, you shouldn’t put your costly HVAC systems at risk by neglecting them. Commercial HVAC systems have more than 100 components — and the potential for accompanying performance issues — that can degrade performance (Building Efficiency Initiative) and cost your business money, so contact Evolution Maintenance today! We can keep your HVAC running at peak efficiency. Contact us

today!

EVOLUTION MAINTENANCE COMMERCIAL HVAC BLOG

5 Signs Your Commercial HVAC System Needs Immediate Attention Your commercial HVAC system is the heart of your business's comfort and operational efficiency. When it's working properly, you barely notice it. But when something goes wrong, it can create a costly disruption—impacting everything from employee productivity to customer satisfaction. Recognizing early signs of HVAC problems can help you avoid expensive emergency HVAC repairs or complete system replacements. Here are five warning signs you should never ignore. 1. Unusual Noises Commercial HVAC systems typically run quietly in the background. If you start hearing banging, clanging, squealing, or grinding noises, it's a clear signal that something is wrong. Possible causes: Loose parts, worn bearings, motor issues. Why it matters: Ignoring unusual sounds can lead to major component failures and higher repair costs. If your HVAC system suddenly sounds like it's struggling, it’s time to schedule an immediate inspection with a trusted commercial HVAC maintenance provider like Evolution Maintenance. 2. Inconsistent Temperatures Are some rooms freezing cold while others feel stuffy and warm? Uneven heating or cooling is more than just an inconvenience—it’s a red flag. Possible causes: Blocked vents, failing compressors, thermostat malfunctions, or ductwork problems. Why it matters: Temperature inconsistencies strain your system and drive up energy bills. Properly diagnosing and fixing these issues early prevents unnecessary energy waste and discomfort for employees and customers alike. 3. Sudden Spike in Energy Bills If your utility bills have shot up without a clear explanation, your HVAC system may be working harder than it should. Possible causes: Dirty coils, clogged filters, refrigerant leaks, or malfunctioning parts. Why it matters: High energy consumption means your system isn’t running efficiently, costing your business money month after month. Scheduling regular commercial HVAC inspections can help pinpoint inefficiencies before they become long-term financial drains. 4. Frequent Cycling If your HVAC system is constantly turning on and off (known as "short cycling"), it's struggling to maintain the desired temperature. Possible causes: Thermostat issues, refrigerant leaks, oversized equipment, or electrical malfunctions. Why it matters: Short cycling stresses your system, causing faster wear and higher repair costs. This behavior can significantly shorten the lifespan of your HVAC unit if not addressed quickly through professional HVAC servicing.\ 5. Poor Indoor Air Quality Bad smells, excessive dust, or a sudden rise in allergy symptoms among employees could point to HVAC system problems. Possible causes: Mold growth, dirty filters, clogged ducts, or stagnant moisture. Why it matters: Poor indoor air quality not only affects health but can also open your business to liability issues and customer complaints. An experienced commercial HVAC technician can assess and resolve indoor air quality problems to keep your environment safe and inviting. Don’t Wait—Protect Your Investment Delaying action when your commercial HVAC system shows warning signs can lead to higher repair costs, lost business, and even complete system failure. Being proactive is key. At Evolution Maintenance, we specialize in rapid response and preventative care for commercial systems of all sizes. If you notice any of these warning signs, don’t hesitate—contact us today for an immediate assessment and expert repair services.

PROTECT YOUR BUSINESS WITH HVAC MAINTENANCE When you manage a business, every dollar matters. One often-overlooked strategy for safeguarding your company’s finances is simple: regular HVAC maintenance. Your heating, ventilation, and air conditioning systems aren't just a comfort feature—they are critical to your operations. Investing in preventative HVAC maintenance can lead to significant savings, improved performance, and a healthier, more productive work environment. The True Cost of Neglected HVAC Systems Ignoring routine commercial HVAC services might seem like a cost-saving measure in the short term, but it often leads to major expenses down the line. Dirty filters, worn-out components, and neglected inspections can cause your systems to work harder, driving up energy costs and increasing the likelihood of unexpected breakdowns. According to industry studies, businesses that skip routine HVAC maintenance face repair costs that are 30% higher on average—and a complete system failure could mean a five-figure replacement cost. Downtime, especially for retail stores, restaurants, or office buildings, also results in lost revenue and unhappy clients or employees. Benefits of Routine HVAC Maintenance Partnering with a trusted provider like Evolution Maintenance for regular HVAC check-ups offers a range of financial advantages: 1. Lower Energy Bills Efficient HVAC systems consume less power. Regular cleaning, lubrication, and inspections ensure that your equipment operates at peak performance, reducing your monthly utility expenses. 2. Extended Equipment Lifespan A well-maintained HVAC system can last up to 40% longer than one that’s neglected. This delays costly replacements and maximizes your original investment. 3. Fewer Emergency Repairs Preventative HVAC maintenance identifies potential issues before they turn into expensive emergencies. Scheduled inspections and tune-ups help your business avoid costly surprise repairs that can disrupt operations. 4. Improved Indoor Air Quality Cleaner air means healthier employees and customers. Regular filter replacements and system cleanings reduce allergens, mold, and bacteria, leading to fewer sick days and a more comfortable environment. 5. Compliance and Safety Regular inspections ensure your systems meet local codes and safety regulations. Non-compliance can lead to fines, insurance issues, or even shutdowns—all of which can hit your bottom line hard. How Often Should You Schedule Commercial HVAC Maintenance? The recommended frequency depends on your industry and usage levels, but most businesses should plan for professional HVAC servicing at least twice a year—typically in the spring and fall. Critical environments like healthcare facilities or food service operations may require more frequent checks. Evolution Maintenance offers customized HVAC maintenance plans tailored to your specific needs, ensuring optimal performance year-round. Protect Your Business's Future with Evolution Maintenance Regular commercial HVAC maintenance isn’t just an operational necessity—it’s a strategic financial decision. By keeping your systems running efficiently, you safeguard your bottom line, protect your people, and support the long-term success of your business. At Evolution Maintenance, we specialize in helping businesses just like yours thrive through proactive, reliable HVAC solutions. Contact us today to schedule your maintenance plan and see how easy protecting your investment can be.